With rapid development of battery technology, silicon gradually beomes a potential negative electrode material. As early as the 1970s, people discovered the electrochemical reaction between lithium (Li) and elemental silicon (Si). Through processing by grinding mill, eg: ball mill, silicon can be well used in negative elsctrode of battery.

The reaction potential of lithium-silicon alloy (LixSi, 0 < x ≤ 4.4) decreases with the increase of lithiation degree. Due to its excellent properties, silicon has attracted extensive attention from academia and industry as the next generation of negative electrode materials. However, we cannot use pure silicon or high-content silicon as negative electrode of battery directly. Why? Let’s analyse it below:

Reasons why pure silicon or high-purity silicon cannot be used as a negative electrode

1. The problem of volume expansion

The volume of silicon changes by more than 280% when it is fully lithiated. The lithium insertion process is like blowing air into a deflated balloon. As the gas content increases, the balloon keeps expanding. While the process of lithium ions removal is like deflating of a balloon, and the volume returns to its original size.

However, as solid particle, silicon does not have good elastic deformation like a balloon. Silicon particles, with continuous expansion and contraction, is very likely to cause serious cracking and pulverization of the anode material and the electrode layer. Under this situation, a new interface between the anode material and the electrolyte will be formed, and it will result in negative impact on electrolyte consumption and SEI thickness.

2.The problem of electrical conductivity

The electronic conductivity of high-purity silicon (< 10−5 S/cm) and the diffusion rate of lithium ions in silicon (10−14—10−13 cm2/s) are much lower than that of graphite. The Electronic conductivity would affect the transmission of electron in anode material, so a good conductive network is of utmost importance. Moreover, the ionic conductivity would affect the process of embedding and extracting of lithium ions and shorten the transmission distance.

So, how to solve this problem? The answer is to combine silicon and graphite.

Adding graphite to silicon material is able to buffer the volume change of the integral composite electrode. Under the condition of low silicon content (about 20%), the main reaction sites for the formation of the solid electrolyte interface (SEI) are provided by graphite particles. Adding graphite to silicon can improve the diffusivity of the electrode and improve the processability in electrode manufacturing, thereby higher energy density would be obtained.

Application prospect of silicon processed by grinding mill in battery negative electrode

Due to high theoretical specific capacity and energy density, silicon can significantly improve the performance of the battery. Silicon-based negative electrode materials, such as carbon-coated silicon oxide, nano silicon carbon, silicon nano wire and amorphous silicon alloy, have a wide application in fields of power battery, energy storage battery and consumer battery now. In the future, silicon-based negative electrode material will become the focus of the battery industry and achieve large-scale commercial application.

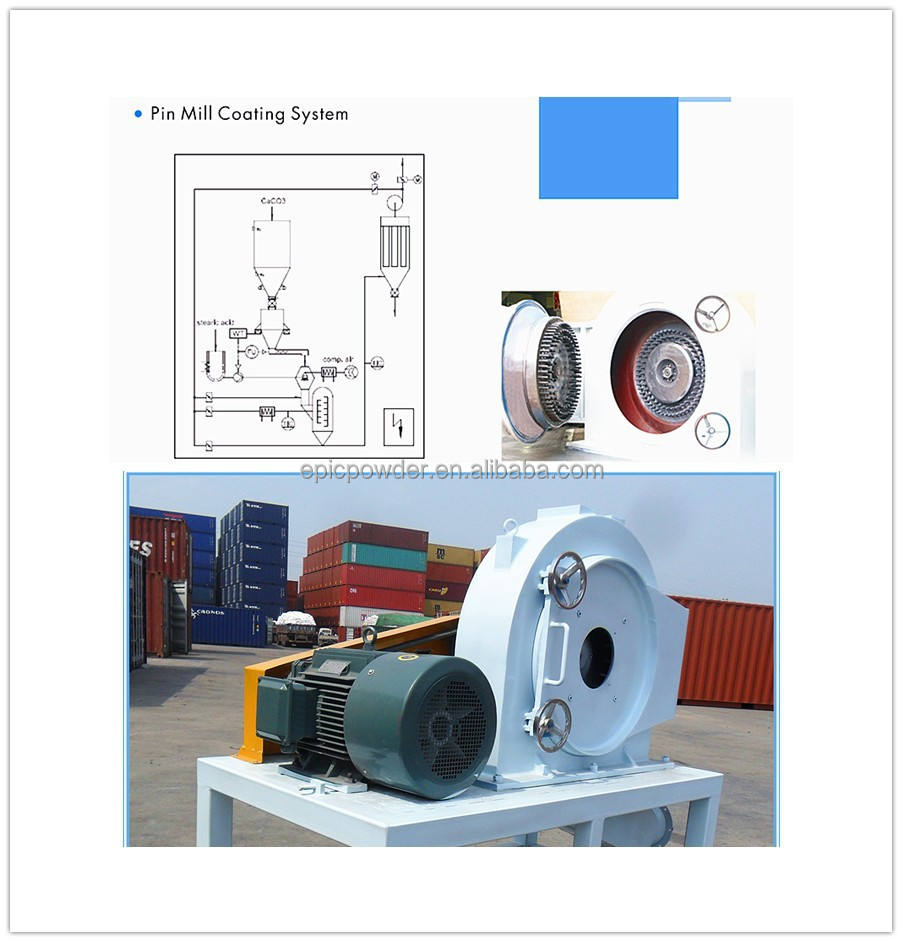

Silicon used in battery negative electrode materials is mainly in nano form, we can obtain nano silicon powser through grinding mill, eg: ball mill. At the same time, in order to improve the electrochemical performance of silicon negative electrode material, modification of silion is necessry. As a professional powder equipment manufacturer, Qingdao Epic Powder Machinery Co., Ltd. can produce ball mill and surface coating modification system for silicon processing. If you have any related needs and questions, please contact Qingdao Epic.

Below are photos for your reference.