Ultra-clear glass is one of the important components of solar photovoltaic cells. With continuous development of solar photovoltaic cell technology, the amount of ultra-clear glass for packaging is gradually increasing, and the market demand is gradually increasing. At the same time, higher requirements are also put forward for the quality of photovoltaic ultra-clear glass, it should be high light transmittance, so iron content needs to be low. In compounding materials of ultra-clear glass, quartz sand accounts for over 60% by weight, and it is the main factor that affects the iron content of the glass.

The quality requirements of photovoltaic glass for quartz sand

The quality requirements of photovoltaic glass for quartz sand mainly include four aspects, they are iron content, titanium content, particle size and refractory heavy minerals.

① Iron content

The obvious difference between quartz sand used in photovoltaic glass and ordinary glass lies in the iron content, the iron content of quartz sand in photovoltaic glass should not exceed 100ppm.

② Titanium content

The titanium oxide in quartz sand will color the glass and reduce light transmittance and transparency of glass, so titanium content of quartz sand in photovoltaic glass should be no more than 300ppm.

③ Particle size

The particle size and grade of quartz sand will affect the quality of photovoltaic glass. The required particle size is 0.71-0.104mm, and proportion of particles below 0.104mm can not exceed 5%.

④ Refractory heavy minerals

Quartz sand contains some chromite and zircon, which are refractory heavy minerals. They are easy to form stones on photovoltaic glass, and affect the processing of finished products. Therefore, the amount of refractory heavy minerals in quartz sand for photovoltaic glass needs to be ≤5ppm, meanwhile, the diameter of single particle needs to be ≤0.25mm.

Purification method of quartz sand for ultra-clear glass

Purification methods of quartz raw material mainly include the following ones:

◊ Water washing and graded desludging

Water washing removes dirt and impurities on the surface of quartz sand by flushing with water, while graded desludging uses hydraulic classification equipment to separate fine-grained dirt and impurities. This method can improve the purity and grade of quartz sand.

◊ Mechanical scrubbing method

Mechanical scrubbing refers to the method that separate iron film and impurities from quartz particles by machine. Specifically, quartz particles collide with each other through external force generated by machine, creating grinding force between particles, this grinding force peels off the iron film and impurities adhering to the surface of quartz sand. In addition, configuration and structure of scrubbing machine, as well scrubbing concentration and time can affect the scrubbing effect.

◊ Magnetic separation

Magnetic separation is to separate magnetic minerals from non-magnetic minerals through magnetic force. This method can removing weakly magnetic impurity minerals, such as hematite, limonite, biotite and ilmenite, that are tightly bonded to the surface of the sand particles; This method can also remove impurities wrapped with magnetic minerals.

◊ lotation method

Flotation method is mainly used to remove feldspar, mica, secondary iron and various non-magnetic associated impurities in quartz sand, by changing the hydrophobicity of mica and feldspar to achieve the effect of separation. According to different activators, flotation can be divided into three types, that are fluorine and acid method, fluorine-free acid method as well as fluorine-free and acid-free method.

◊ Acid leaching method

Based on the fact that quartz is insoluble in acid (except HF) and impurity minerals containing Fe can dissolve in acid, leaching method can remove iron-containing minerals from quartz sand. The acid leaching method can remove iron-containing minerals from quartz sand. The commonly used acids in acid leaching method include sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid and oxalic acid. These acids, especially hydrofluoric acid, have very good effect on the removal of Fe, Al and Mg, but hydrofluoric acid is the most harmful to the environment.

◊ Microbiological method

Microbiological method is to remove iron film or impregnated iron on the surface of quartz particles by microorganism. This is a new type of iron removal technology, and currently it is in the laboratory research stage. The research shows microbial flora has good removal effect to iron oxide on the surface of quartz sand. The microbial flora includes Aspergillus niger, Penicillium, Polymyxa and Lactococcus etc. Among them, Aspergillus niger has the best iron removal effect.

◊ Ultrasonic iron removal method

Ultrasonic iron removal method is the method that removing iron impurities of quartz particles through ultrasonic waves. Specifically, use ultrasonic waves to generate shock waves during cavitation process in water. With this method, iron impurities are peeled off from the surface of quartz particles through shock waves. By doing this, the aim of iron removal can obtain. This method can effectively remove secondary iron film on the surface of quartz particles. However, its cost is expensive, so it usually have application in high value-added and precision silicon industry.

Postscript

Natural quartz can apply to ultra-clear glass only after grinding and classifying, its iron content and particle size should be in certain range. Meanwhile, to improve the performance of quartz sand in ultra-clear glass, modification of quartz particles is also necessary.

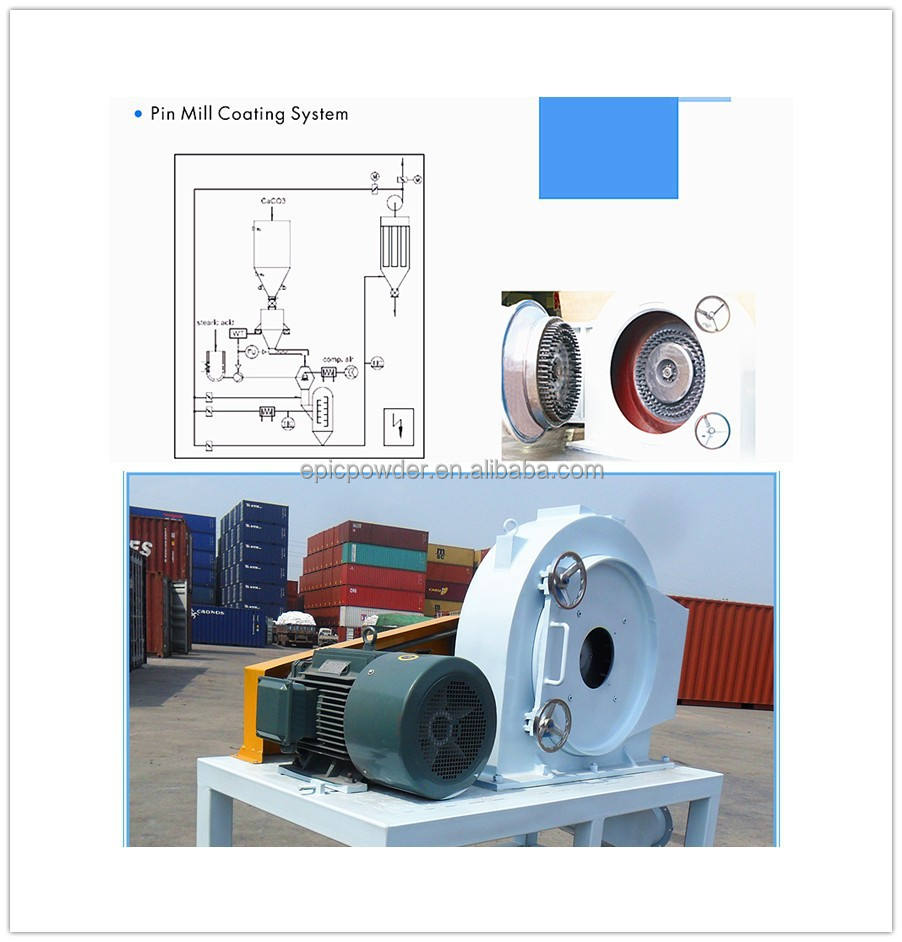

Qingdao Epic powder machinery Co., Ltd is a professional manufacturer of powder machinery, it has rich experience in producing powder machinery of non-metallic minerals. Their products include: ball mill, jet mill, air classifiers and modifiers. These equipment can work individually or together as a production line, and they are popular in both domestic and foreign markets.

If you have related question or demand, please feel free to contact Qingdao Epic.