1. Introduction

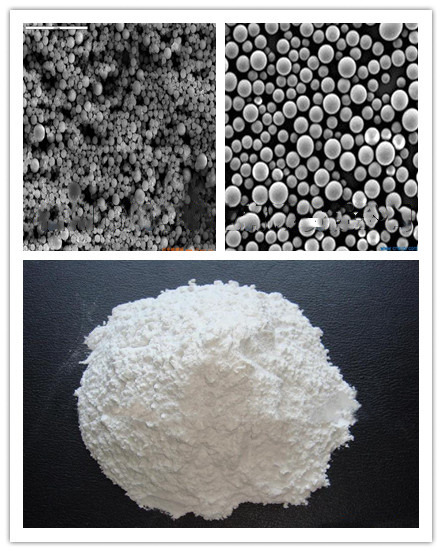

Spherical silica powder is a kind of silica powder with spherical particles, its main component is silicon dioxide. With characteristics of good dielectric property, good thermal conductivity and low expansion coefficient, spherical silica powder is widely used in fields of electronic device packaging, aerospace, coatings and cosmetics, etc.

2. Production methods

Depending on whether chemical changes occur, the production methods of spherical silica powder can be divided into physical method and chemical method. Physical methods include: mechanical grinding method, spray method, flame spheroidization, plasma method and high temperature calcination spheroidization method, etc. Chemical methods mainly include: gas phase method, precipitation method, hydrothermal method, sol-gel method and microemulsion method, etc.

Next, we will talk about some of the main methods specifically.

2.1. Mechanical grinding method

By using professional crushing equipment and auxiliary screening equipment, spherical silica powder can be obtained. This method is suitable for producing ultra-fine silica powder.

2.2. Spray method

Dissolve silicon source (such as silicate) in an appropriate solvent to form a uniform solution. Then spray out the solution through spray device, and the droplets are rapidly pyrolyzed under high temperature. Finally, silica powder is obtained.

2.3. Flame spheroidization

This method needs to do some preprocessing of crushing, screening and purifying on high-purity quartz sand. And then send quartz powder into a high-temperature field generated by gas-oxygen for high-temperature melting. Next, the molten powder is cooled, and finally high-purity spherical silica powder is obtained.

2.4. plasma method

The method uses angular silica powder as raw material. First, process angular silica powder through crushing, screening and purifying, and then adopt high temperature flame melting method to melt it instantly at high temperature with acetylene or natural gas as heat sources, next, quickly cool into balls, finally silica powder with high purity and uniform particles is obtained.

3. Summary

With continuous improvement of production methods, the application of spherical silica powder will be further expanded. In practical applications, its production usually requires procedures of crushing, screening, purification and classification, etc. It requires strict control of the formula and equipment to ensure the quality and performance of finished products.

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder machinery. The ball mill and air classifier produced by Qingdao Epic are suitable for grinding and classifying of spherical silica powder, and they have good reputation among customers.

Our main products include:

– Mills: ball mill, air classifier mill(ACM), roller mill, jet mill, turbo mill and impact mill, etc.

– Classifiers: include four series of air classifiers: HTS, ITC, MBS and CTC.

– Surface coating modifiers: pin-mill modifier, turbo-mill modifier and three-roller-mill modifier, etc.

– Auxiliary equipment: control cabinet, dust collector and bucket elevator, etc.

– Customers can customize products according to actual needs. One customer, one design.

If you are interested in ball mill and air classifier or other products from Qingdao Epic, contact our staff directly, we are always at your service.

Below are photos from Qingdao Epic for your reference.