Ball mill+ Classifier

· The ball mill adopts special design and appropriate proportion of grinding medium to achieve ideal grinding fineness. The discharge of grate plate is smooth, and the cylinder does not need cooling;

· The feeding of ball mill is controlled continuously to ensure the stability of feed. Even if the feed density changes, it can also ensure the accuracy and achieve the highest grinding efficiency;

· Add polyols, polyamide and other grinding aids, through the metering pump quantitative injection, to ensure accurate ratio. Improve the grinding efficiency and product performance stability, ensure that the products have more advantages in the application of plastics, coatings and paper fillers;

· By using different combinations of single classifier or multiple classifiers, products with different fineness can be produced at the same time, or the product specifications can be changed at any time according to the market requirements, which has greater flexibility. The classification capacity of our multi rotor classifier can reach 90% 2 μm. both the classification accuracy and the output represent the world advanced level;

· The classifier is equipped with speed sensor and control system, which can measure, evaluate and compensate the air temperature, air pressure and air volume, as well as the pressure loss caused by the increase of filter pressure difference, so as to ensure the product quality and quality stability;

· High quality level indicator is used in the silo to ensure the automatic control of the production process;

· The conveying system is manufactured according to DIN and ISO standards with high stability;

· The whole line adopts automatic control system to achieve stable load of equipment and ensure low energy consumption;

· World class automatic packaging and palletizing system, pollution-free, including minimization, suitable for long-distance transportation;

· The filter has high dust collection capacity, which meets the requirements of European environmental protection. The dust emission of environmental protection dust collector in pure air is less than 1mg/m³;

· This processing system is equipped with detection and control devices, which can meet the quality requirements of ISO9000 and ISO9001. This is becoming more and more important in the international market;

· Provide a full set of turnkey projects, from the design of the entire production line, equipment installation and commissioning to personnel training and other technical services. It also provides the design of peripheral equipment, such as crushing, cleaning, drying, transportation, storage, packaging, mineral processing and laboratory equipment;

· We can reduce the investment of users by the following ways: some or all of the equipment is produced or purchased in China according to our engineering and technical requirements, the existing equipment and production line are updated and transformed, part of the second-hand equipment is provided, and technical consultation and project management are provided;

· Fully understanding the product and raw material market of calcium carbonate, as well as the requirements of end users for products, can provide technical support for users’ market development, and enable users to maintain a leading edge in the fierce market competition.

Working Principle and Equipment type features

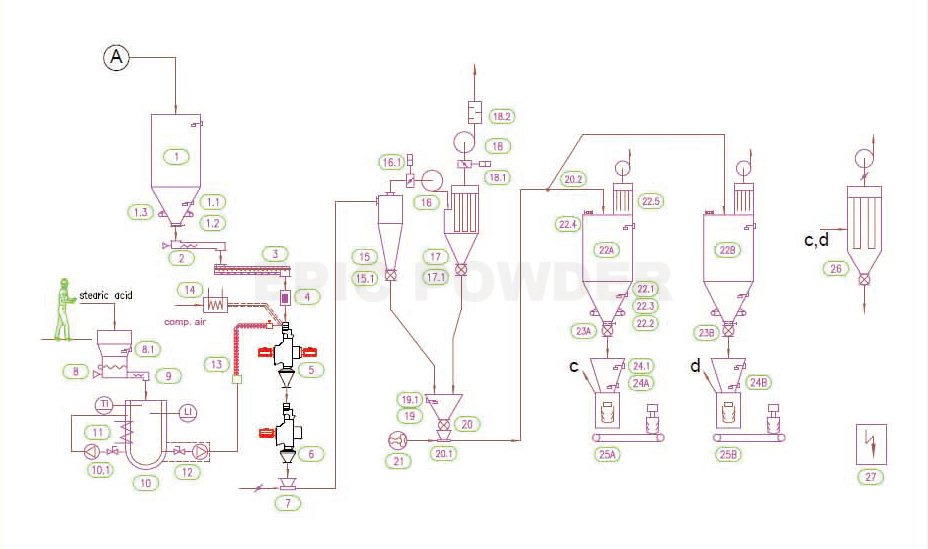

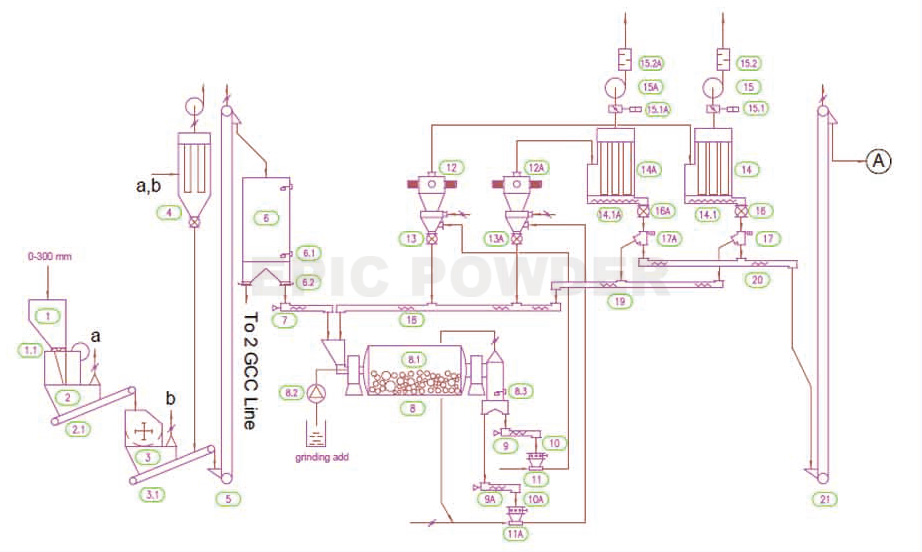

The production line adopts internationally popular batch continuous production process: ball mill and classifier system. Including crushing, grinding, classifying, packaging, magnetic separation, conveying, lifting, etc. After the ball mill, classifiers can be connected in parallel or in series to simultaneously produce products with multiple particle sizes.

Working principle: equip with various grinding medias (steel balls, steel rods or gravel, etc.). When the cylinder rotates around the horizontal axis at a certain speed, the medium and raw materials contained in the cylinder will be fall off from the cylinder as the cylinder reaches a certain height under the action of centrifugal force and frictional force, milling the ore due to the impact force. At the same time, during the rotation of the mill, the sliding movement between the grinding media also has a grinding effect on the raw materials. The milled material is discharged through hollow journal.

Major Equipment of ball mill and air classifier production line

Ball mill

· The lining plate and grinding medium are manufactured according to German standards, which extend the service life of the grinding medium and improve the wear resistance. According to the requirements of product fineness, the size and material of grinding medium are designed to improve the grinding efficiency;

· The grinding energy consumption is reduced to the greatest extent, and the energy and operation cost are saved.

Classifier

· Originated from German technology, it is divided into vertical turbine classification and horizontal turbine classification;

· Accurate frequency conversion control ensures perfect classification accuracy;

· The structure of the classifier is optimized, the path of material and air flow is more reasonable, the air volume of classification is adjustable, the classification efficiency and flexibility are improved;

· The new NG rotor design improves the classification accuracy, reduces the resistance and reduces the energy consumption.

Control system

· PLC control, high degree of automation, easy to operate; easy to integrate with other system programs, easy to manage;

· Both the material silo and product silo have leveler, which can realize automatic control of the entire production line;

· Touch screen man-machine interface, convenient process control and adjustable parameters.

Quantitative system

· Ball mill feedstock adopts a precise quantitative system, which can stabilize the feed even if the density of the material changes;

· Classifier feedstock adopts a precise quantitative system and interlocks with the discharge of the ball mill to ensure the stability of the system operation and product granularity;

· High-precision metering pump, according to fineness requirements of product, spray the grinding aid into the mill with accurate time and dosage;

· The damper valve has an airflow measurement system that allows accurate control of the flow volume and rate of classifying.

Environmental protection and noise control

· The whole system operates under negative pressure, and there is no dust overflow, realizing clean production;

· Adopt efficient muffler, exhaust noise<80dB(A);

· All heavy-duty moving parts have shock absorbers;

· There is no waste water discharge.

Main equipment specifications and parameters of ball mill classifying production line

| Model | 1530 | 1557 | 1850 | 1860 | 1870 | 2250 | 2260 | 2270 | 2460 | 2450 |

|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder diameter (m) | 1.5 | 1.5 | 1.83 | 1.83 | 1.83 | 2.2 | 2.2 | 2.2 | 2.4 | 2.4 |

| Cykinder length (m) | 3 | 5.7 | 5 | 6 | 7 | 5 | 6 | 7 | 5 | 6 |

| Motor power (kW) | 75 | 132 | 160 | 220 | 250 | 250 | 320 | 380 | 320 | 400 |

| Feeding size (mm) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Fineness (μm) | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 |

| Model | 2470 | 2660 | 2665 | 2670 | 3070 | 3080 | 3090 | 3270 | 3280 | 3290 |

|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder diameter (m) | 2.4 | 2.6 | 2.6 | 2.6 | 3 | 3 | 3 | 3.2 | 3.2 | 3.2 |

| Cykinder length (m) | 7 | 6 | 6.5 | 7 | 7 | 8 | 9 | 7 | 8 | 9 |

| Motor power (kW) | 475 | 500 | 560 | 630 | 800 | 900 | 1000 | 1000 | 1250 | 1400 |

| Feeding size (mm) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Fineness (μm) | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.