Quartz is a common mineral found in many rocks and soils. It is widely used in the manufacturing of glass, ceramics, and other industrial products. One of the most important applications of quartz is in the production of high-quality silica sand, which is used in a variety of industrial processes.

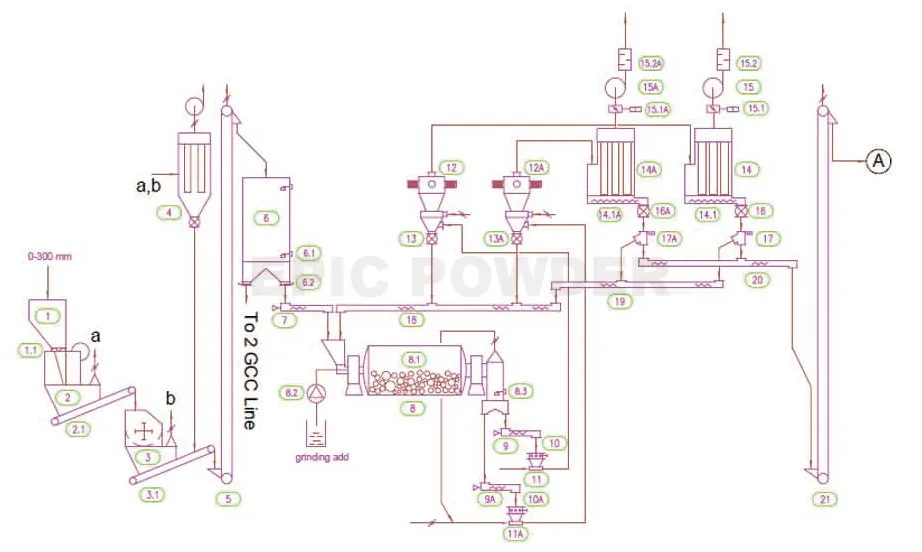

Quartz Ball Mill Classification Production Line Equipment Introduction

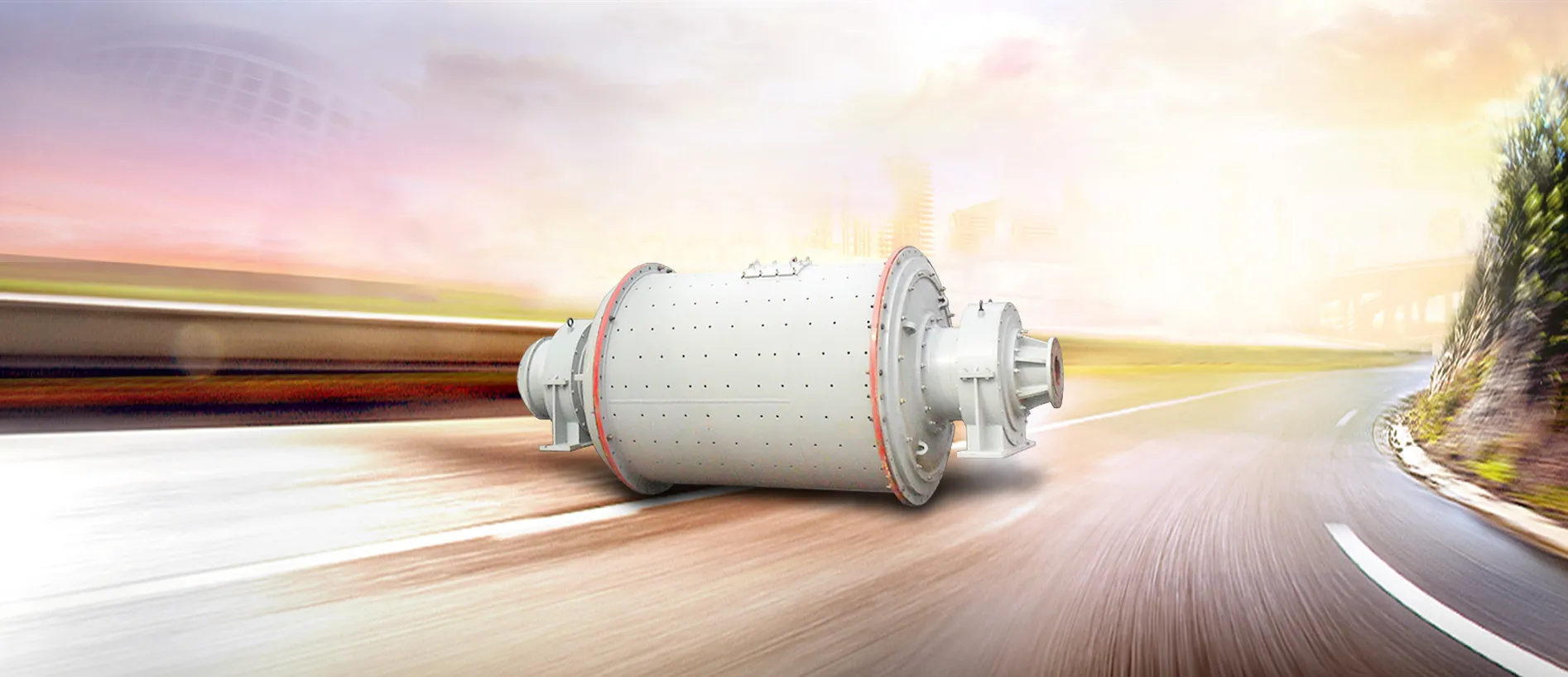

- Quartz Ball Mill: The quartz ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

- Classifier: The classifier is mainly used to grade the particles in the grinding process. The classifier can be used to separate the coarse particles from the fine particles, and to control the particle size distribution of the final product.

- Magnetic Separator: The magnetic separator is used to remove the iron impurities from the quartz particles. The magnetic separator can effectively improve the purity of the final product.

To produce high-quality silica sand, quartz needs to be crushed and ground into fine particles. This is typically done using a ball mill, which is a type of grinding machine that uses steel balls to grind materials into a fine powder. However, the process of grinding quartz can be time-consuming and inefficient, which can lead to low output and high production costs.

To improve the efficiency and output of the quartz ball mill classification production line, several strategies can be employed. One of the most effective strategies is to use a classification system, which can help to separate the fine particles from the coarse particles. This can help to reduce the amount of time and energy required to grind the quartz, which can lead to a significant increase in efficiency and output.

Another strategy that can be employed is to use a high-pressure grinding roll (HPGR) instead of a ball mill. HPGRs are designed to reduce the energy required to grind materials, which can lead to a significant increase in efficiency and output. Additionally, HPGRs can help to reduce the amount of dust and noise generated during the grinding process, which can improve the working environment for operators.

Finally, it is important to ensure that the ball mill is properly maintained and operated. This includes regular inspections and maintenance, as well as proper training for operators. By following these best practices, it is possible to improve the efficiency and output of the quartz ball mill classification production line.

In conclusion, the production of high-quality silica sand requires efficient and effective grinding of quartz. By employing strategies such as classification systems and HPGRs, and by properly maintaining and operating the ball mill, it is possible to significantly increase the efficiency and output of the quartz ball mill classification production line.