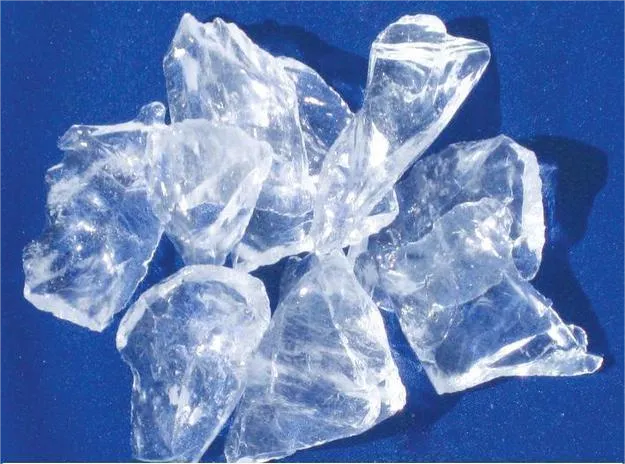

Silica powder is a functional powder material made from natural quartz (SiO₂) through crushing, grinding, purification and grading. As an important industrial mineral material, quartz powder has a wide range of applications. According to different particle sizes, quartz powders have different application fields due to their different physical and chemical properties.

1〕Ultra-fine quartz powder (D50 < 10μm)

Application fields

High-end coatings/inks: As a functional filler, to improve wear resistance and weather resistance (such as automotive paints and marine coatings).

Electronic packaging materials: used for semiconductor epoxy resin packaging to reduce the coefficient of thermal expansion (CTE).

Cosmetics: UV scattering agent in sunscreen (replacing part of TiO2). The particle size needs to be 200-400nm.

Pharmaceutical carrier: controlled-release drug coating material, requiring amorphous silica and sterility.

Key technical indicators: specific surface area (BET)>10m²/g, strict control of heavy metal content (such as Pb<5ppm).

2〕Fine quartz powder (10-50μm)

Application fields

Precision casting: Silica sol binder for investment casting, narrow particle size distribution can reduce surface defects of castings.

Rubber industry: Reinforcing fillers (such as silicone rubber), the tear resistance is best when the particle size is 20-30μm.

Ceramic glaze: To reduce the firing temperature (fluxing effect), it needs to be compounded with zircon powder to prevent glaze cracking.

Process requirements: Surface silanization treatment (such as KH – 550) is required to improve the interfacial bonding force.

3〕Medium particle size (50-200μm)

Application fields

Filtering medium: Frac sand (40 – 70 mesh) for petroleum industry, requiring a roundness of ≥ 0.6 and a compressive strength of > 50 MPa.

Glass raw materials: In the production of flat glass, particles of 200μm can reduce “silicon floating” in the melting furnace.

3D printing materials: Silica sand for selective laser sintering (SLS), the fluidity must meet the Hall flow meter <25s/50g.

Special treatment: Acid washing (HF immersion) to remove surface iron impurities, achieving Fe₂O₃ content <0.01%.

4〕Coarse particles (>200μm)

Application fields

Metallurgical flux: Deoxidizer in steel plants (1-3mm), dosage with CaO in a 2:1 ratio.

Water treatment filter material: Quartz sand (0.5-1.2mm) for multi-layer filter tanks, uneven coefficient K80≤1.5.

Photovoltaic industry: Quartz crucible raw materials (5-20mm) for polysilicon ingot casting, purity requirement SiO₂>99.99%.

Economic advantage: The cost of crushing and screening is only 1/5-1/10 of that of fine powder.

Frontier application directions

Submicron level (500nm): Modified quartz fiber reinforced material for 5G base station high-frequency PCB boards.

Nanoscale (<100nm): Barrier coating for quantum dot displays (requires vapor phase process).

From the above we can see that quartz powder has broad application prospects. At the same time, in quartz powder processing industry, efficient and stable ball mill (commonly used mill in quartz grinding) is the key for enterprises to gain a foothold in the market and enhance their competitiveness, and it is also an important step to start efficient production and achieve profit growth. Qingdao Epic Powder Machinery Co., Ltd. is a professional manufacturer of powder processing equipment. Our products include: powder grinding equipment, classifying equipment, modification equipment and related auxiliary equipment. We are committed to providing excellent powder processing solutions for companies.

If you are purchasing ball mill for grinding quartz or other material, or other powder processing equipment, please contact Epic Powder, and we’ll provide you a one-stop solution from equipment selection, solution design to installation and commissioning, and after-sales service.

Contact us, and let our professional equipment make your powder processing more efficient and intelligent!