Introduction to quartz powder

Quartz powder is a very important inorganic non-metallic functional filler. Its main component is SiO2. Quartz powder is white in color, we can get it from natural quartz ore through crushing, washing and grinding. Modification of quartz powder can improve the processing performance of material and reduce the cost, it has become an indispensable material in many industrial fields.

Reasons and types of quartz powder modification

Quartz powder is a polar, hydrophilic substance. Different from polymer matrix, quartz powder has poor compatibility, it is usually difficult to disperse in the base material. To get better performance of composite material, surface modification of quartz powder is necessary. It can improve compatibility of quartz powder with organic polymer material, and improve its dispersibility and fluidity in polymer materials. The commonly used methods for quartz powder modification include: coating modification, dry modification, wet modification and composite modification.

Effect of properties

The properties of quartz powder directly affect its combination with surface modifier. The properties include: particle size, specific surface area and surface functional groups. Spherical quartz powder has good fluidity, it is easy to combine with the modifier during modification, and can be well dispersed in the organic polymer system.

Application in artificial quartz stone

Artificial quartz stone slabs are made of quartz powder, quartz sand, unsaturated polyester resin, curing agent and coupling agent, through process of mixing, pressing, heating and curing, and polishing, quartz powder is obtained. As a filler, quartz powder can not only reduce the consumption of unsaturated resin, but also improve the performance of wear resistance, acid and alkali resistance, and mechanical strength of artificial quartz slabs. The application principle of modified quartz powder in artificial quartz stone lies in its compatibility with resin. Compared with unmodified quartz powder, modified quartz powder can significantly improve the properties of dry flexural strength, compression strength, abrasion resistance and glossiness of the quartz stone slabs.

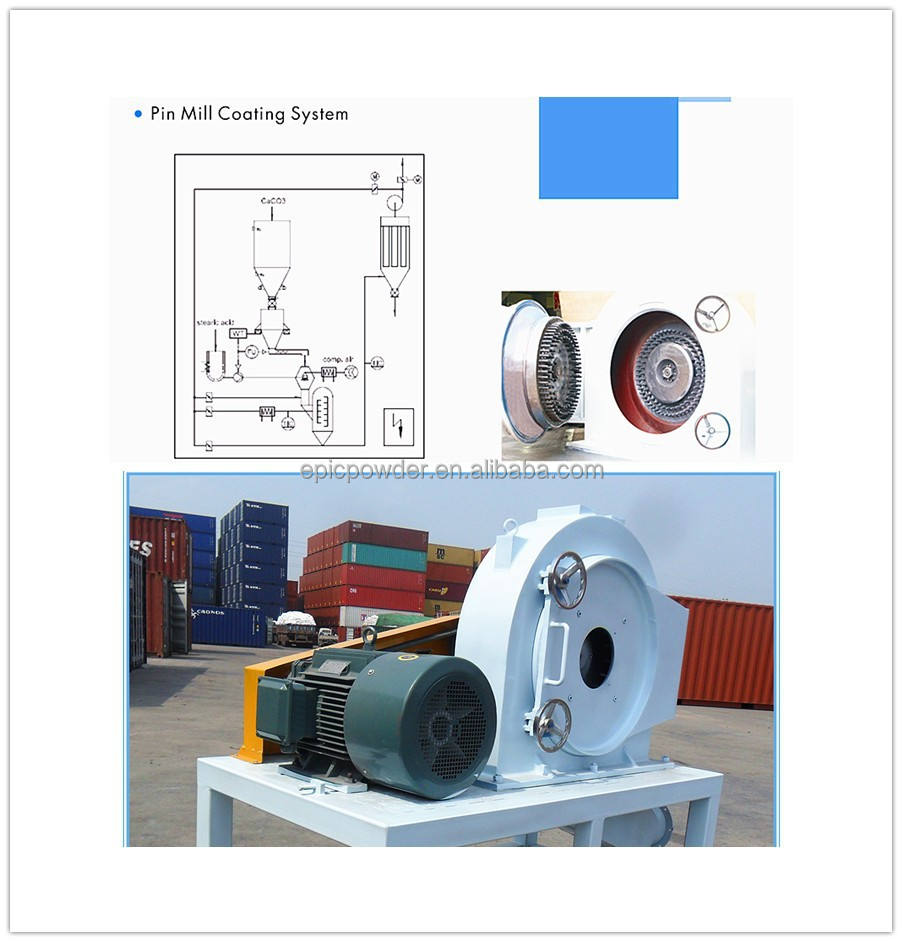

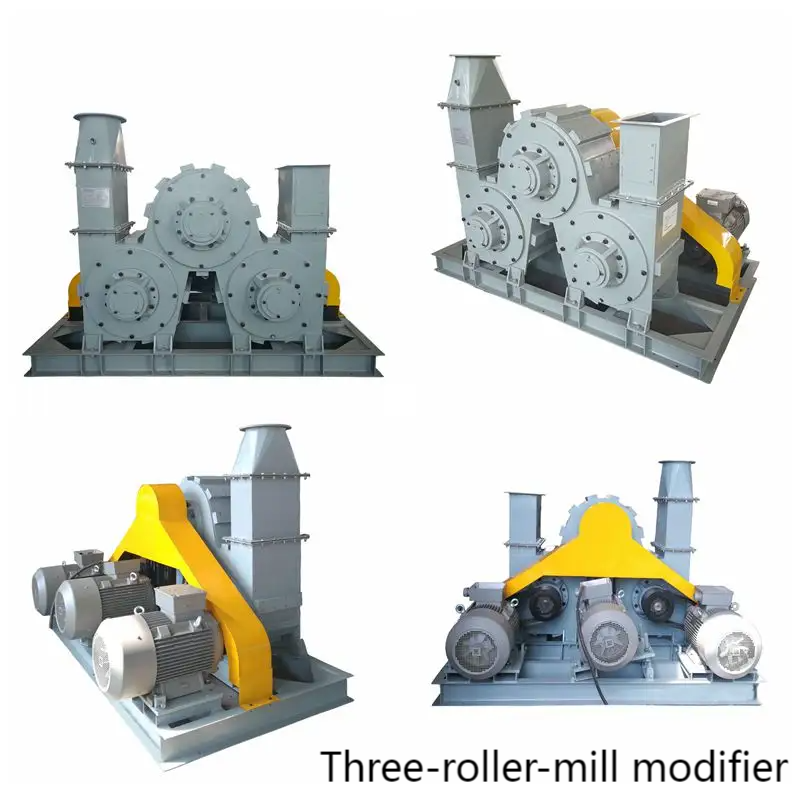

The modification of quartz powder undoubtedly requires the use of modifier. Qingdao Epic Powder Machinery Co., Ltd. is a specialized manufacturer of powder processing machinery. Its equipment includes: jet mill, ball mill, roller mill, air classifier and surface coating modifier. For surface coating modifiers, Qingdao Epic has developed four continuous modifiers, including: pin-mill modifier, turbo-mill modifier, three-roller-mill modifier and multi-rotor-mill modifier. These continuous modifiers are very suitable for the modification of quartz powder.

If you have any related needs or questions, please contact Qingdao Epic directly.