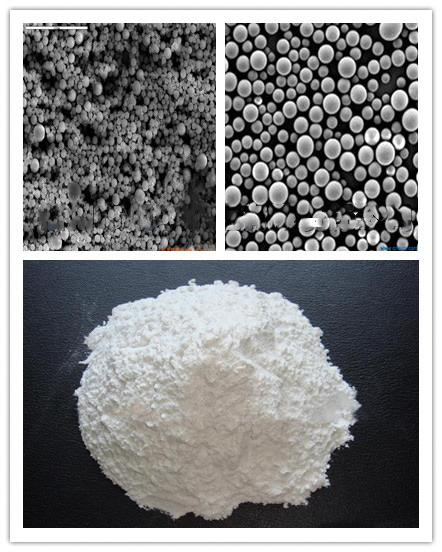

1. What is spherical silica powder

Spherical silica powder is an inorganic non-metallic material. It is odorless, non-toxic and non-polluting, and its main component is silicon dioxide (SiO2). It has advantages of high purity, fine particles, good fluidity, low stress and small specific surface area, and the application of spherical silica powder includes many aspects, below let’s talk about it.

2. Main application areas of spherical silica powder

Spherical silica powder has a wide range of applications. Next,Let’s talk about its main application areas:

1)For copper clad laminate

Spherical silicon powder can improve electrical ductivity, mechanical property and thermal conductivity of copper clad laminates. The appropriate input ratio of spherical silicon powder is 5%~10%. Too high or too low a ratio will affect the performance of copper clad laminates.

2)For EMC (epoxy molding compound)

Spherical silica powder plays a vital role in epoxy molding compound (EMC). Epoxy molding compound is the main material for sealing electronic devices and integrated circuits. Spherical silica powder, as a filler of EMC, accounting for 60%-90% of EMC. The performance of spherical silica powder directly affects the viscosity, fluidity and electrical insulation of epoxy molding compound.

3)For honeycomb ceramics

Honeycomb ceramic carrier for automobile exhaust purification is made from spherical silica powder with alumina and silicon powder etc. Spherical silicon powder can improve the molding rate and stability of honeycomb ceramics.

4)For paints and coatings

Spherical silica powder can significantly improve the performance of coatings. For example, when spherical silica powder being added to interior wall latex paint, the stain resistance, thixotropy, wash resistance, water resistance and aging resistance are significantly improved. In addition, spherical silica powder can improve the fineness, leveling performance and film hardness of the coating, shorten the grinding time, and enhance anti-rust and anti-corrosion properties of coatings.

5)For adhesive

When used in adhesive, such as: building structural adhesive, spherical silica powder can improve its properties of viscosity, thixotropy and anti-sagging.

3. Summary

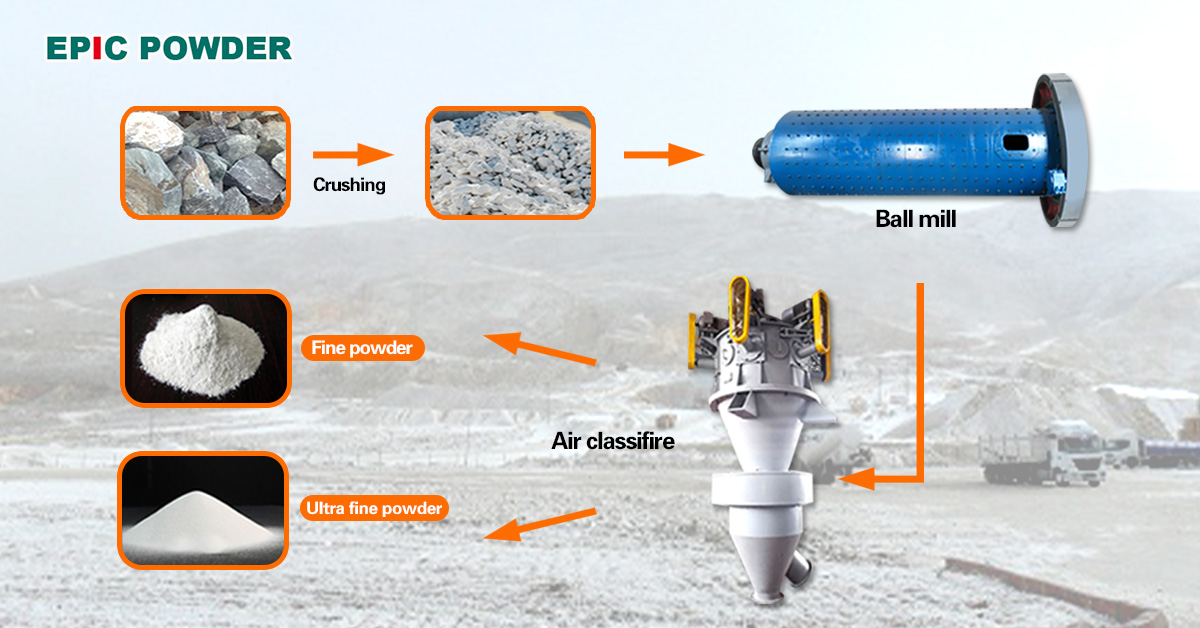

As a functional industrial material, spherical silica powder has a broad application prospect. In practical applications, particle size distribution of silica powder is required to be within a certain range, so classifying of silica powder is necessary. The air classifier produced by Qingdao Epic Powder Machinery Co., Ltd. is suitable for classification of spherical silica powder.

Qingdao Epic Powder Machinery Co., Ltd. is a manufacturer specializing in the production of powder machinery.

Our main products include:

– Mills: ball mill, roller mill, air classifier mill(ACM), turbo mill and impact mill, etc.

– Classifiers: four series of air classifiers: HTS, ITC, MBS, CTC.

– Modifiers: pin-mill modifier, turbo-mill modifier and three-roller-mill modifier, etc.

– Auxiliary equipment: control cabinet, dust collector and bucket elevator, etc.

– Customers can customize products according to actual needs. One customer, one design.

If you have related needs or questions for air classifier or other products, please feel free to contact Qingdao Epic, our staff is always ready to serve you.

Below are photos from Qingdao Epic for your reference.