Quartz is one of the most widely distributed minerals on Earth, and it is extensively present in various rocks, such as granite and sandstone. Meanwhile, quartz has characteristics of good abrasion resistance, high temperature resistance, and excellent optical properties. These features enable quartz a wide application in many fields, such as glass, ceramics, photovoltaics, electronics, and refractory materials.

However, in practical applications, in order to meet different particle size requirements and application effects of quartz in various industries, grinding and classification on quartz are essential.

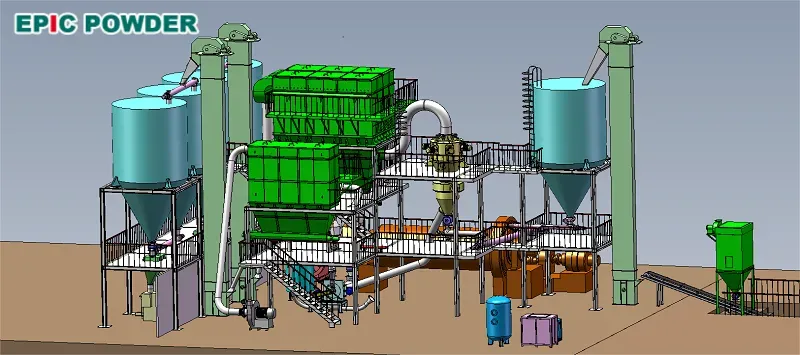

The ball mill+classifier production line produced by Qingdao Epic Powder Machinery Co., Ltd. is suitable for grinding and grading quartz, and it has significant advantages, especially in terms of particle size control, energy consumption optimization, purity maintenance, etc. The following is a detailed analysis:

1. Controllable particle size, suitable for high value-added applications

— High-hardness material grinding

Quartz has high hardness (Mohs 7). The ball mill can efficiently grind quartz from 45μm to 200 mesh or even finer (such as D97≤10μm) through the impact and friction of steel balls/ceramic balls. With ball mill grinding, quartz can meet particle size requirements of high-end quartz powder, such as: photovoltaic glass, electronic-grade silicon powder, high-purity quartz sand.

— Classifier for precise classification

Equipped with air classifier (turbine classifier), qualified particles can be separated in real time to avoid over-grinding. This can ensure a narrow particle size distribution of the finished product (such as D90/D10≤3), and improve product consistency.

2. Optimize energy consumption and reduce production costs

— Ball mill + classifier collaboration to reduce energy consumption

The ball mill + classifier production line adopts a closed loop of “grinding-separation”, and only circulates the coarse particles. This can effectively avoid over-grinding and reduce energy consumption by 20% to 30%.

3. Maintain purity and reduce iron pollution

— Choose good materials

Ceramic lining + alumina balls or high chromium alloy lining is used to avoid iron mixing and ensure SiO₂purity ≥99.9% (electronic grade requirement).

— Closed system design

The whole system operates under negative pressure, which reduces contamination of external impurities, and it is especially suitable for the processing of high-whiteness quartz.

4. Automation and large-scale production

— PLC control

The ball mill speed and classifier air volume can be adjusted in real time to adapt to the hardness differences of different quartz ore sources.

— Flexible production capacity

A single production line can reach 5~50 tons/hour, and through multi-level grading, it can simultaneously produce quartz products of various specifications (such as 325 mesh, 800 mesh, 1250 mesh).

5. Environmentally friendly and easy to maintain

— Dust removal system

Pulse bag dust removal or cyclone dust removal, dust emission ≤20mg/m³, in line with environmental protection requirements.

— Modular design

Modular design allows ball mill and classifier to be quickly installed and maintained, reducing downtime for maintenance.

The above is an overview of the advantages of ball mill + classifier production line from Epic Powder for processing quartz. It is an internationally advanced non-metallic minerals production line with large output and high efficiency, and is very popular in the market and among consumers.

As a professional manufacturer of powder processing equipment for many years, we have accumulated rich production and technical experience. Our products include: powder grinding equipment, classifying equipment, modification equipment and related auxiliary equipment. If you are purchasing quartz processing equipment or other powder processing equipment, please contact Epic Powder. We will provide you with a one-stop solution from equipment selection, solution design to installation and commissioning, and after-sales service, and we hope that our professional equipment can help you make powder processing more efficient and energy-saving.